The project involves the development of a technology for assessing the condition of insulation and the risk of failure of MV cable lines. As a part of industrial tests, a Health Index will be developed for cable line elements. Then, based on the Health Index, a prototype IT system will be prepared to assess the risk of failure in cable lines. The new technology will be verified and calibrated during tests carried out in the pilot area. The project will be realized by the consortium: Energa Operator and Globema.

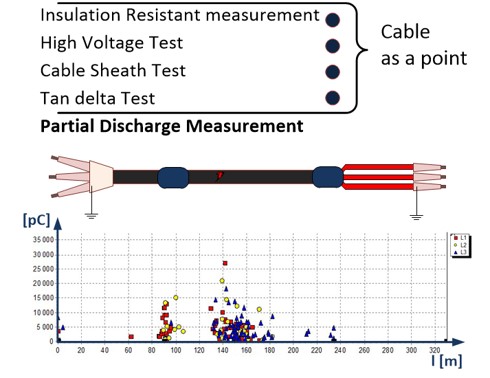

Diagnostics methods

Tan Delta Measurements

The healthiness of an electrical insulator can be determined by the ratio of the resistive component to the capacitive component, creating a loss factor. The VLF test voltage is applied across the tested equipment. First, the normal voltage is applied. If the value of tan delta appears good enough, the applied voltage is raised to 2 times of normal voltage. Analyzing the results of the loss factor for normal voltage and higher voltages will give accurate information about the insulation state. If the insulation is perfect, the loss factor will be approximately the same for all range of test voltages. But if the insulation is not sufficient, the value of tan delta increases in the higher range of test voltage.

Partial Discharge Measurements

DAC and VLF voltage waveforms are typically used for diagnostic measurements. Based on examinations carried out for the SORAL project, it has been found that: The most common parameter indicating the risk of the failure is reduced PD ignition voltage and the occurrence of increased PD intensity in a power cable. The study shows that, the lower the PD ignition voltage, the higher the percentage of cable sections of an increased PD intensity. the partial discharge measurements provide data on each part of the cable line.

Benefits

- Reducing or eliminating power outages caused by cable failure

- Improving SAIDI and SAIFI rankings – improved quality of the distribution

- Reducing maintenance costs due to reduced numbers of failures and forced field surveys

- Cost and time efficiency gained because of the condition-based maintenance and planned maintenance based on the health index